Sand Filters

Sand Filters

Recirculating

Recirculating

Recirculating Sand Filters (RSF) are an excellent method for bringing wastewater up to advanced treatment levels, especially when the volume and strength exhibit large fluctuations. Even with these fluctuations, biological oxygen demand (BOD) & total suspended solids (TSS) levels below 10 mg/L and total nitrogen reductions of 40-50% can be expected.

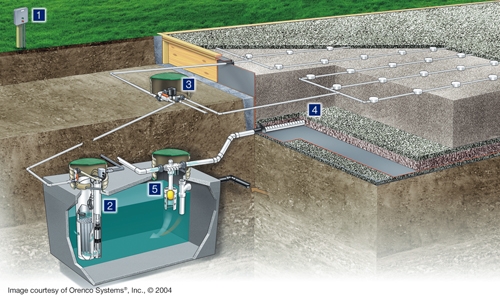

A typical recirculating sand filter consists of a recirculation tank containing a:

(1)Control panel.

(2)Biotube® Pump package,

(3)Distributing valve assembly,

(4)Manifold kit, and

(5)Recirculation splitter valve.

Effluent is received from the primary septic tanks into the recirculation tank where it mixes with the treated effluent. The pumps in the recirculation tank distribute the mixed effluent over the filter media in small frequent doses using a time dosed control panel. The effluent percolates through the coarse sand where its contaminants are removed and broken down by naturally-occurring microorganisms living on the sand particles. A series of collection lines in the base of the sand filter return the treated effluent to the recirculation tank where it mixes with the incoming wastewater. After a few more passes through the system, the treated wastewater is ready for discharge. The recirculation splitter valve and the liquid level controls the amount of effluent discharged. However, no more than 20% of the effluent is discharged, thus a minimum of 80% is returned to the tank for mixing with the incoming wastewater and further treatment

Complete RSF kits from Orenco Systems® can handle every onsite treatment need, from a 300-gallon per day installation to a million-gallon per day effluent sewer system. Typically installed flush-to-ground, they're the ideal solution for treating commercial waste from restaurants, schools, or RV parks. Orenco RSFs require little power to operate, and there's no need for a full-time operator. An Orenco Recirculating Sand Filter makes sense when treatment quality is important and cost matters.